Sector description

Industrial machines are very energy intensive running on a 2 or 3 shift basis or even fully autonomous, up to 24h a day. Therefore the other product life cycle phases are in most case less important and the use phase should be focused.

Details

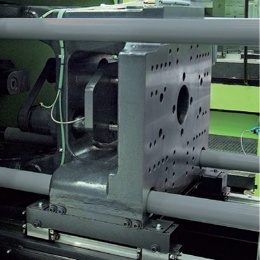

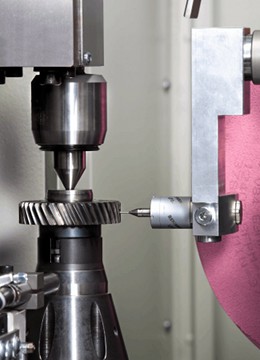

Machine tools, furnaces, rolling machines, pump compressors, plastics processing machines and machines for welding, soldering, brazing etc. are included in this sector.

![[example img]](grafik/sectors/im-laser700x700s.jpg)

In this sector Germany has the highest production value followed by Italy and United Kingdom. The annual EU-27 production volume of metal working machine tools is roughly 200.000 units, that of wood working industrial machinery 130.000 units and 60.000 plastics and rubber processing machines. The market of welding, soldering, and brazing equipment covers roughly 1.400.000 units sold EU production. Machinery building is an important economic sector of the EU, dominated by SMEs.

The sector of industrial machines is characterised by design trends like increasing complexity and higher degree of automation to comply with performance requirements and high productivity.

Industrial machines are a core sector of the European high-tech industries, consuming a huge share of overall power consumption of the EU-27, but this also represents a huge savings potential, once energy-efficient system solutions and components are integrated. Creating transparency regarding the life cycle impacts of industrial machinery helps to create a level playing field for the equipment manufacturers and incentivizes those, with the most eco-efficient products. LCAs of Industrial Machines are particularly challenging due to the complexity of the equipment and as they are customized configurations in most cases.

Case Studies

- Kapp Werkzeugmaschinen GmbHde

- Posalux S.A.

- Gleason-Pfauter Maschinenfabrik GmbHde

- Oberflächentechnik GmbH

- Leobersdorfer Maschinenfabrik GmbH

- Burri Werkzeugmaschinen GmbH & CoKGde

- Logiboxx from Haumberger Fertigungstechnik GmbHde

- WFL Millturn Technologies GmbH & CoKGde

- Anger Machining GmbH

- Ateliers Noël & Fils S.A.

- Bio-Circle Surface Technology GmbHde

- Krause & Mauser GmbH

- Raptor2650 from Pamminger Verpackungstechnik GmbH

- SBM Mineral Processing GmbHde

- SEMA Maschinenbau GmbHde

- 600UK Ltd

- Sonplas GmbH

![[LCA to go]](grafik/logos/our/c-fa-110s.png)

![[EU Logo]](grafik/logos/eu/eu-flag75x50m.png)